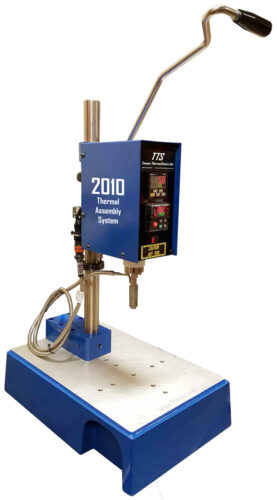

These lever-arm, manually operated systems are ideal for single-point or small, multi-point assembly operations. Each unit is exceptional for short-run prototype work, hot blade degating, off line repairs, date coding, branding and for testing new applications. The 2010T Manual Heat Staking Assembly System has a built-in digital timer. The operator can set and adjust the cycle time, ensuring that each part is assembled for the same amount of time. This improves part-to-part consistency and reliability. Ideal for laboratories and molding houses.

Features

- Blanchard ground cast aluminum machine base

with 3/8-16 fixture mounting holes - Adjustable, locking depth stop for accurate tool adjustment

- Microprocessor-based temperature controller with digital display of set point and process value readout

- 80-999° F operating range +/-2 degree accuracy

- Non-asbestos insulator

- Easy-access on/off switch

- Easy adjustable head height

- Durable powder coated finish on all sheet metal surfaces

Specifications

- Power requirements: 110 VAC, 50/60 Hz

- Current draw @ full rated output: 5 amps

- Stroke length: 2.5″ (6.3 cm)

- Maximum force: 120 lbs.

- Weight: 34 lbs.

Custom Options (Quoted Upon Request)

- Part holding nest and upper tooling for a complete turnkey assembly system

- Extended column height

- Post cooling system

- 3″ x 3″ multi-point platen

- Cartridge Heater

Additional Features for the 2010T

- 0.1 second to 1 hour adjustable digital assembly timer

- Magnetic switch that starts timer (not shown)

Item# TBY004

2010 Heat Staking Assembly System (1 Heat Zone)

Item# TBY007

2010T Heat Staking Assembly System (Timer & 1 Heat Zone)